Introducing the Overwatch System for Fire Detection, Notification, and Suppression Response

Features Include

- Fire Alarm Control Panel (FACP) features four signaling line circuits (SLCs), each with up to 254 intelligent devices (1016 devices per FACP)

- Panel-to-panel communication over dual-port Ethernet (copper or fiber) with rapid spanning tree rings

- RS-485 and Ethernet communications to third party devices using common industrial protocols and custom messaging

- FACP and Annunciator feature advanced PCAP touch panel that supports gloved-hand operation

- FACP provides 42Ah, 28Ah, or 13Ah battery back-up power to connected devices in the event of a loss of primary power

- Comprehensive zone support including pre-alarm, alarm, and discharge with timers, grouping, and cross-zone functionality

- Ability to run custom algorithms in parallel with Fire Detection functionality

- Temperature Range: -30°C to +60°C (-22°F to +140°F) Operating, -30°C to +80°C (-22°F to +176°F) Storage

- MIL-STD-901D / MIL-STD-167B / MIL-STD-461E qualified (pending)

- Can construct a fully UL-compliant (pending) system using listed components for implementing everything from ship-wide fire & smoke detection to local detection & actuation systems

- Robust security features, including role-based user authentication access control, tamper seals, intrusion detection and logging, encrypted communications and data wiping

Downloadable Brochure

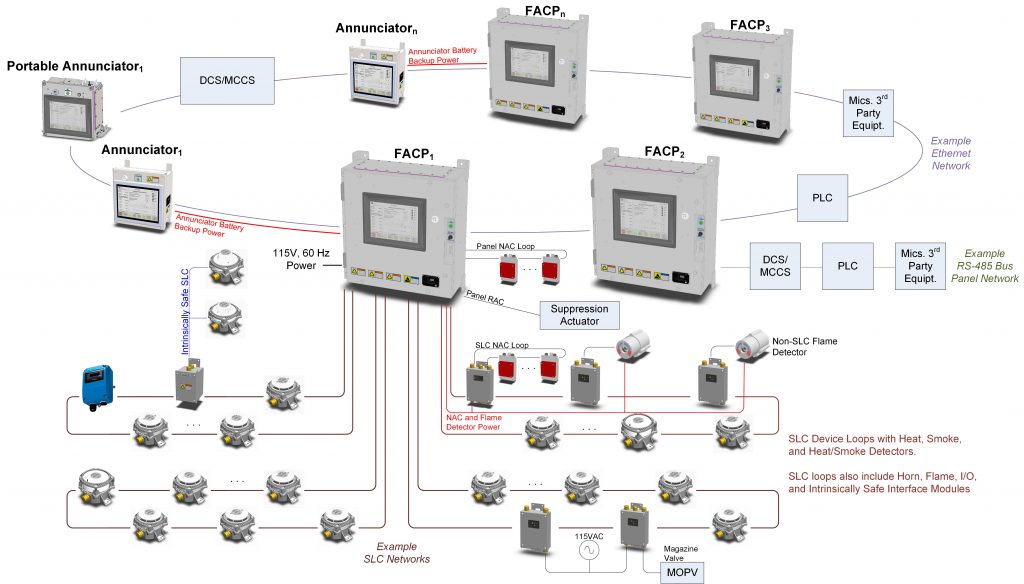

Above is an example architecture using Fairmount Automation’s Overwatch Fire Detection System (FDS) product line. FDS heat detectors, smoke detectors, combination smoke/heat detectors, flame detectors, sounder modules, I/O modules, and notification appliances connect to Signaling Line Circuits (SLCs). These SLCs can be routed in a Class X loop topology from the FACP to a group of detectors/modules and back to the FACP (Class A and B bus topologies are also supported). SLCs distribute power from the FACP to the attached devices, and also serve as a bi-directional communication channel between the FACP and Apollo fire detectors/modules. Each SLC can accommodate up to 126 XP95 or Discovery (legacy) addressable devices or up to 254 Core Protocol addressable devices.

SLC Notification Appliance Circuits (SLC NACs) connect the SLC to notification appliances through an addressable control module. These appliances are powered from the FACP auxiliary output power. An example Motor Operated Pilot Valve (MOPV) is activated through an AC output and its power monitored by an AC input.

Notification appliances can be directly connected to the panel using its one internal NAC.

The panel also contains one Releasing Actuation Circuit (RAC) to provide a supervised connection to a fire suppression agent actuator. The RAC connection includes functionality to actively monitor the health of an actuator coil.

The FACP processes signals from system input devices to generate warning and/or alarm signals. Those signals are indicated visually and audibly at the FACP operator interface. They can also activate SLC output devices.

The FACP incorporates an internal, rechargeable battery that allows the FACP and attached devices to continue to operate on loss of AC input power. The FACP actively charges its internal battery whenever input power is available.

Annunciator and Portable Annunciator Panels have a user interface and networking capability identical to the FACP but lack I/O interfaces and a local battery backup (backup power can be provided from other sources such as an FACP).

Additionally, each FACP/Annunciator can exchange information (alarms, sensor data, etc.) with any of the following ships supplemental services using one of the many supported common industrial automation protocols or via a custom message format:

- Distributed Control System (DCS),

- Machinery Centralized Control System (MCCS),

- other 3rd party networked equipment (programmable logic controllers, computers, pumps, etc.)

Supported network configurations include support for RS-485 and Ethernet (Copper and/or Fiber) bus topologies.